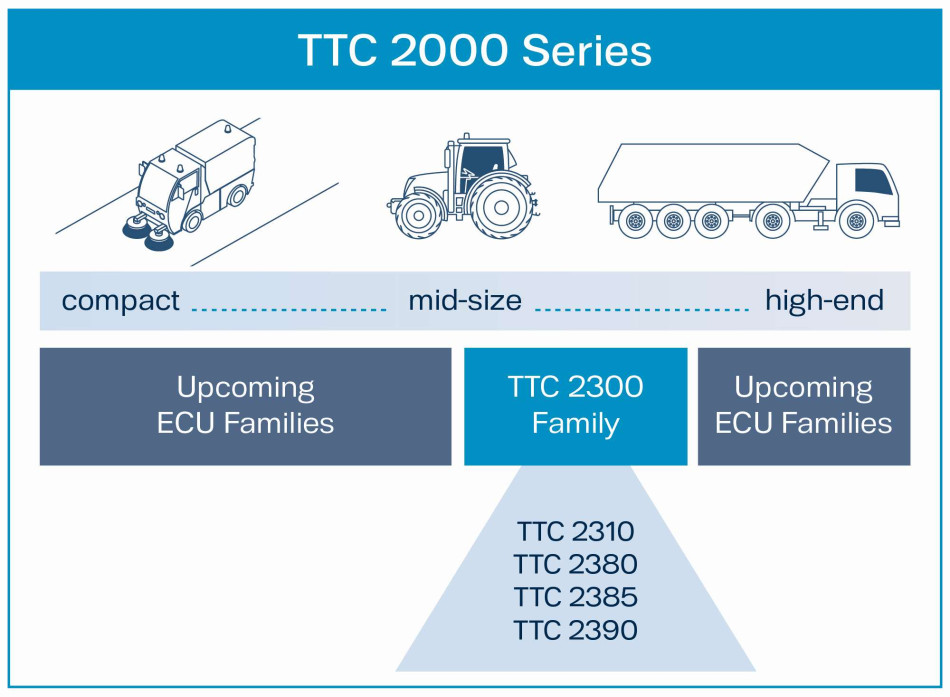

TTControl arranged a virtual product launch event to present the TTC 2300 family, its latest generation of electronic control units (ECUs) for vehicle manufacturers. This now available ECU family is the first member of TTControl’s complete and scalable TTC 2000 series designed to meet the needs of automated and smart off-highway vehicles and mobile machines.

High processing power, high-speed connectivity and a large memory make these robust ECUs the ideal choice for advanced electronic architectures and future automation and assistance systems. They are designed for use in rugged operating environments and operate under harsh conditions and extreme temperatures.

“The TTC 2300 family is part of an upcoming complete ECU series that shares the same basic building blocks, making them fully compatible with one other,” says Christiana Seethaler, Vice President Product Development at TTControl. "This allows our customers to use the same set of development tools, for example compilers, debuggers and the build environment, for every member of this ECU series. Since the API is also fully compatible with each ECU, it is easy to port an application to the next ECU family as the requirements increase."

Lead customer sees potential for exclusive ECU solution

At the launch event, Severin Wiesmüller, Global Product Manager HMI and Electronics at Rosenbauer, the world’s largest producer of fire-fighting vehicles, explained why the modular control series has the potential to become the exclusive ECU solution for Rosenbauer’s fire trucks and special vehicles. "The freedom from interference between the safety-related and non-safety-related parts is one of the biggest assets of the TTC 2300 family. We are able to continuously add country-specific features without having to recertify all the software on our fire trucks."

"Due to the high flexibility of the TTC 2300 family, we can use one ECU type in all our products. This greatly simplifies and accelerates our development cycles and makes it easier for our international customer service team," he adds.

Faster time-to-market for off-highway markets

The TTC 2300 family is TUeV certified to meet the safety standards of the agricultural, construction and automotive industries. This helps to significantly reduce certification costs for vehicle manufacturers.

The freedom from interference allows both safety-critical and non-safety-critical code to run on the same CPU without reducing the overall safety level. This ensures that there is no impact on the safety-critical components of the software when non-safety-critical code is changed, therefore eliminating the need to validate the entire system. Infineon’s latest high-performance CPU, the second-generation AurixTM TriCoreTM, ensures the right computing power and is ready for future mobile machines. Combined with the safety-certified real-time operating system PXROS that allows to make full use of the AurixTM multicore architecture, the TTC 2300 family reduces the time to market.

New levels of onboard connectivity

The TTC 2300 family is designed for high-speed communication over Ethernet with other vehicle components, such as telematic gateways for interfacing with cloud-based functions. The TTC 2300 family enables use cases for various automation and assistance systems thanks to the large internal memory and transmission of smart sensor data via standardized SENT (Single Edge Nibble Transmission) interfaces.

The first member of a modular ECU series for smart machinery

The TTC 2300 family is the first member of the upcoming TTC 2000 series, which will consist of a wide range of compatible ECU families that scale from small and compact versions for less demanding applications to large versions with extended memory, more CPU cores and a very extensive set of I/Os and interfaces.

With the TTC 2000 series and its first ECU family, the TTC 2300, machine manufactures will be able to future-proof their machinery. The ECUs offer full flexibility to reuse applications regardless of machine size and for future machine generations. The TTC 2000 series variants will offer scalable building blocks that make the control system expandable as needed to adapt to rapidly evolving vehicle technology.