This article was first published in the iVT Magazine, Off-Highway Annual 2020, November 2019

By Arno Purkrabek, team lead product management at TTControl

Our world is constantly moving, or as the Greek philosopher Heraclitus of Ephesus was quoted as saying, “everything changes and nothing remains still.” In our daily life, we are used to constant interaction with machines and tools such as smartphones and household appliances. The way we interact with these gadgets is changing. The same is true for the interaction of human operators with mobile machinery, like construction or agricultural vehicles such as excavators, wheel loaders and combine harvesters. Manufacturers of mobile machinery continue to improve the efficiency and safety of these machines in the face of operators’ changing expectations regarding the human-machine interface (HMI). Operators themselves are not a homogeneous group. On the one hand, there are machine operators with over 20 years of experience in handling mobile machines. On the other are young operators – digital natives – who have grown up with high-end computer games and smartphones. Consequently, OEMs of mobile machines are forced to find new approaches in the design and development of modern HMI.

Assisting the operator

TTControl, a joint-venture company of TTTech and HYDAC International, is a leading supplier of electronic control systems, operator interfaces and connectivity solutions. It supports vehicle OEMs in developing new approaches with its new generation of rugged operator interfaces called Vision 3. Vision 3 offers an excellent answer to the latest requirements for HMI on mobile machinery. The enhanced automation of machine functions and the demand to continuously increase the number of assistance systems are among the trends that machine manufacturers must consider in order to remain competitive. Due to the significant shortage of skilled operators, a modern machine should be easy to operate with minimal training efforts. The number of repetitive tasks and the workload should be reduced for the human operator. The reduction in fuel and time consumption due to the optimized working process not only results in cost savings for the fleet owner but also reduces polluting emissions.

Multiple interfaces for an intuitive overview

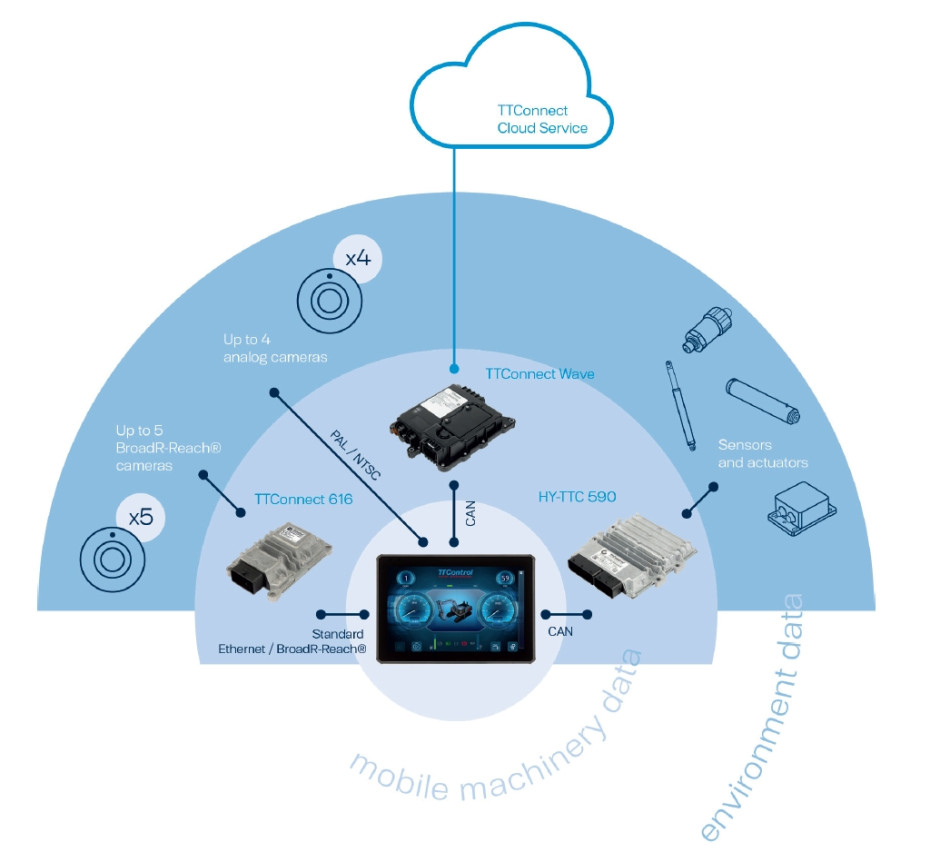

When approaching these trends from a system architecture perspective one main issue emerges – data collected by the ever-increasing number of sensors must be processed so that it can be intuitively presented to the operator. Not only do the cameras and sensors connected to the machine provide information about the machine’s surroundings, but sensor data coming from the environment itself will also be visualized for the operator. For instance, data retrieved from other mobile machinery, or even robots and drones, will be merged and presented in an intuitive graphical representation of the environment.

Therefore Vision 3, TTControl’s third generation of displays featuring Vision 312 and Vision 312Plus, comes with numerous communication interfaces. Up to four CAN interfaces are available for visualizing the machine data. One of these CAN interfaces is ISOBUS-compliant and can transform the Vision 312Plus device into an ISOBUS Virtual Terminal, which is important in applications for agricultural machines like tractors, combine harvesters, and for implements. In addition, the displays are available with up to two USB interfaces and a serial interface. The Ethernet interface is available either as standard Ethernet (100BASE-TX) or as BroadRReach (100BASE-T1). BroadR-Reach is the evolution of traditional Ethernet and uses unshielded single twisted pair cables, resulting in reduced connectivity costs and cabling weight. This allows the connection of high definition digital cameras, a prerequisite for further image processing like object or person detection. Up to five BroadR-Reach Ethernet cameras can be connected when combined with TTConnect 616, TTControl’s rugged Ethernet switch. However, analog cameras may still be preferred for many applications, particularly as not all vehicle designs will be immediately upgraded with digital cameras. Therefore, the Vision 3 display series supports the direct connection of up to four analog cameras as well.

IoT in the Off-Highway Market

Another megatrend of recent years is the Internet of Things (IoT), which is highly relevant for the off-highway machinery sector. There is a multitude of advantages for both fleet owners and for human operators as a result of vehicles being connected to the cloud, enabling remote diagnostics or software updates. This connectivity technology has supported the emergence of new features, bringing about entirely new use-cases and business models. TTControl’s Vision 3 display series and its set of interfaces combined with TTControl’s IoT platform TTConnect Cloud Service prepares mobile machinery for the next level of connectivity.

Seamless integration

From a systems perspective, a modern operator interface needs to be designed for seamless integration into the electronic architecture of the vehicle. The display’s communication interfaces are also used to exchange data with the electronic control units which control the vehicle and its working functions. An example is TTControl’s latest controller HY-TTC 590 that allows the use of the CAN bus or the BroadR-Reach Ethernet interface.

Operator comfort and user experience

Operator comfort and sophisticated user experience (UX) are further requirements for an innovative HMI in the world of modern mobile machinery. TTControl’s Vision 3 displays feature very fast boot-up times to ensure operator comfort right from the start. To enable a high-quality user experience in line with modern consumer devices,

which are not rugged enough for use in the off-highway sector, a large and brilliant screen is essential. To fulfill these expectations in terms of user experience, TTControl has equipped their Vision 312 operator interface with a large, optically bonded 12.1in LCD screen with a high state-of-the-art resolution of 1280 x 800 pixels and a wide viewing angle. With a brightness of up to 1,000 cd/m², it ensures perfect sunlight readability. The projective capacitive touchscreen enables intuitive user inputs and can even be operated with gloves.

The power to perform

Assistance systems and multimedia require significant computational power. As a result, Vision 3 electronics are equipped with a 4-Core CPU with an extensive memory. This powerful CPU is paired with a sophisticated cooling concept to ensure high computational power under all environmental conditions. In addition, it allows for the simultaneous display of up to four camera streams and enables multimedia features such as interactive operator manuals in video format. For full multimedia experience, the integrated loudspeaker can also be used; for less sophisticated applications, a variant with a single-core CPU is available. When it comes to different kinds of use-cases and to take full advantage of the electronics, the Vision 3 operator interface is programmable with CODESYS or alternatively with C/C++ and Qt.

Ready for the future

Despite all this change, there is one thing which has not changed over the years and that is the harsh environment off-highway machinery is operated in. The extensive experience of TTControl pays off when merging the world of electronics, connectivity and operator comfort and the world of the off-highway sector, with extreme temperatures and unforeseen weather conditions. We know that the best CPU only achieves its high performance with a sophisticated cooling concept and the best communication interface only works reliably in harsh environments with the right high-speed connectors. Therefore, TTControl has designed and optimized Vision 3 from the very first design stage onwards for the harsh environment it operates in.