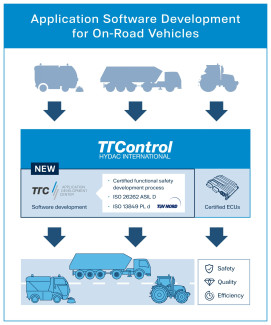

TTControl’s application software development processes are ISO 26262 certified by TÜV Nord

- Vehicle manufacturers using TTControl-developed application software and functions meet initial process requirements for a high level of road safety up to ASIL D

- TTControl supports its customers throughout the vehicle certification process for a successful software certification according to ISO 26262

- This helps vehicle manufacturers to significantly reduce time-to-market while improving software quality and safety

- Vehicle manufacturers save costs and resources to set up an ISO 26262-compliant process which can require more than 5,000 working hours

- The development process, which has now been certified, has already been used successfully in the development of Rosenbauer's latest firefighting vehicle: the Rosenbauer RT

Vienna, Austria, May 19 - TTControl has recently received ISO 26262 certification from TÜV Nord for its software development processes. Vehicles using application software developed by TTControl thus meet the process requirements for a high level of road safety up to Automotive Safety Integrity Level D (ASIL D). Vehicle manufacturers, therefore, have to invest significantly less time and effort in the certification process for mobile machinery. ISO 26262 compliance is mandatory for vehicle control unit functions for example for municipal vehicles, trucks and busses.

"As our electronic control units have been certified, our application development processes follow. We offer a certified quality standard for individual applications and support the customer throughout the vehicle certification process for successful software certification according to ISO 26262," says Janosch Fauster, Director of TTControl's Application Development Center. "Functional safety has always been part of our service. While our customers are working on their latest innovative product, we support them in achieving the required safety goals and getting their product on the road in compliance with international and European standards”.

Setting up an ISO 26262-compliant process can cost a vehicle manufacturer more than 5,000 hours in time and financial investment in external consultants. Seamless process integration also requires hands-on experience and fine-tuning over many years. Subsequent discussions about process details with notified bodies during a project can lead to further delays and redesigns. TTControl's now-certified software development process helps vehicle manufacturers accelerate the certification process and reduce its complexity.

TÜV Nord has certified approximately 35 internal procedures at TTControl for compliance with ISO 26262:2018 for vehicles of more than 3.5 tons. The certified process has already been successfully applied in practice by TTControl's in-house Application Development Center. The experts have helped optimize the safety certification of Rosenbauer's latest firefighting vehicle, the Rosenbauer RT, and ensure the functional safety of the complex hybrid-electric vehicle architecture.

As more and more software functions are integrated into modern vehicles, functional safety is becoming increasingly important. Being the international standard for road vehicle functional safety, ISO 26262 defines a procedural model for reducing potential hazards that can result from malfunctions of electrical and electronic (E/E) systems. To comply with ISO 26262, manufacturers must check all individual elements that can lead to malfunctions during the development phase. Using software and functions developed under certified processes can help to significantly reduce time-to-market. Vehicle manufacturers benefit from freeing up internal resources to leverage product-related development and innovation projects.

Over the past 20 years, TTControl has built up extensive functional safety expertise in application development. TTControl’s inhouse Application Development Center has implemented more than 100 safety functions for its global customer base to support an efficient development phase. These include functions required by safety standards to prevent unintended acceleration, excessive torque or accidental shifting into reverse gear on-road vehicles. Safety features can automatically influence the maximum speed of a refuse truck when an operator is on the rear platform. Or they limit the maximum reach of an aerial work platform depending on the weight in the basket in relation to the stabilization weight.

Media materials

|

|

|