Reaching dizzying heights and moving mountains – Hinowa makes it possible

The Italian company, headquartered in Verona, looks back on 35 years of company history: Since 1987, it specializes in manufacturing aerial and earthmoving machinery. Highest quality and innovation are of utmost importance – especially when working at a height of 30 meters.

But whether working at a height of 13 or 33 meters, safety standards must be met. To ensure this, Hinowa has been working with TTControl for years. The joint-venture between TTTech and HYDAC International is a leading provider of functional safety and ensures that safety requirements are met in the cooperation with Hinowa. This includes additional safety standards and requirements for work platforms, the safe use of mobile elevating work platforms, and the safety of machine controls. Together with the customer, TTControl implemented the full electro-hydraulic control of the machine, from track control to stabilization and aerial kinematics.

Building Safety Block By Block

Hinowa offers its customers not only mobile elevating work platforms with extensive equipment, but also great flexibility with different models, different ranges, and several motorization options. Thus, the customer can choose between gasoline or diesel combustion engine, 400V 3-phase motor, Li-Ion-powered electric motor or even a combination of these. Zero-emission options are also available, which are best suited for indoor or city center applications.

But it is precisely this flexibility that poses a major challenge on the side of software and electronics: Despite different drive options, unified and consistent operational handling as well as maximum performance must be ensured. Even machines that have already been released must be upgraded with new functions while ensuring safe equipment design. The software must be exceptionally well developed when operating at over 30m. Through our design approach we focus on reducing risk through continued evaluation of our technology.

This is ensured by an experienced team of engineers at Hinowa and TTControl, who are focused on developing strong, reliable solutions. To enable a flexible and modular electronics architecture that allows Hinowa to use the same building blocks for a wide range of machines, a software framework was created. This covers all the base functionality and can easily be expanded as needed via additional, modular functions. An extensive set of regression tests also ensures that modifications have only the desired impact on already released functionality.

Behind The Scenes: TTControl in Action

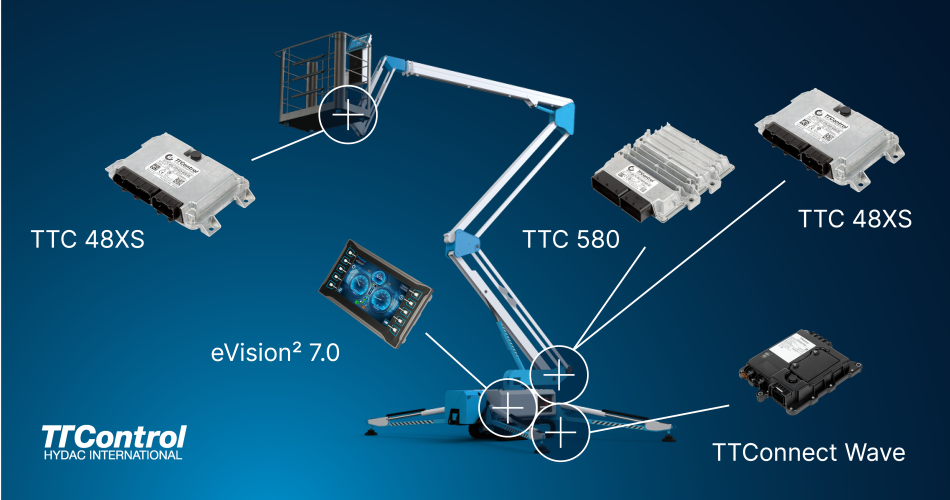

All machines at Hinowa are equipped with a central TTC 580 controller and a TTC 48XS module, which is used as an I/O extension and uses CANopen Safety. For larger models that require more connections, a second I/O module from TTControl can be integrated, allowing the above-mentioned modularity in the system.

The largest machines also feature a 7-inch display with eVision² 7.0 that gives the operator easy access to configuration options at the base of the vehicle. Finally, TTControl also provides IoT connectivity through TTConnect Wave, which allows software updates and performing diagnostics via access to Hinowa's remote access system.

(c) TTControl

The robust hardware is extremely reliable thanks to safety certified ECUs: TTControl’s application software development processes are ISO 13849 and since 2022 also ISO 26262 certified, meeting initial process requirements for on-road and off-road safety applications. This way Hinowa benefits from high machine availability. Powerful microprocessors with high-resolution I/Os allow precise control of all movements and enable smooth, precise, and consistent aerial movements.

Rising High Hand in Hand

For work at great heights to run smoothly, it needs a solid foundation. The bedrock foundation of success in this project is the strong cooperation between Hinowa and TTControl. The companies are also closely linked in their corporate philosophy: Both are committed to drive innovation and excellence in engineering in their respective fields. This is proven by the technology awards Hinowa received at Intermat 2018 and by the IAPA Award 2021.

Years of successful collaboration have been defined by a well-coordinated team that unites colleagues from TTControl and Hinowa. "We don’t see TTControl as a simple supplier but as a technology partner," says Zeno Poltronieri, General Manager at Hinowa.

(c) Hinowa

Both companies strive for the highest quality and full commitment to get the working platform not only done right, but also to the customer in time. The absolute focus on this objective, the exchange of ideas within the team and the mutual support in the various areas, from hydraulics to electronics and software to system design, as well as a trusting and open feedback culture were important building blocks for establishing good communication and encouraging innovation.

"I’m convinced that a solid, open, trust-based, objective-driven long-term partnership with key technology suppliers provides a clear path to success for OEMs, especially when it comes to the area of software development, which is increasing exponentially in complexity," says Janosch Fauster, Director Application Development Center. TTControl has been developing applications for end customers for more than 20 years, has optimized development processes, implemented more than 100 safety functions and works with a state-of-the-art development environment. More than 20 specialized software developers support customers in implementing advanced software functions that work reliably under all conditions. This allows Hinowa to fortify its market leadership with each new model they release.